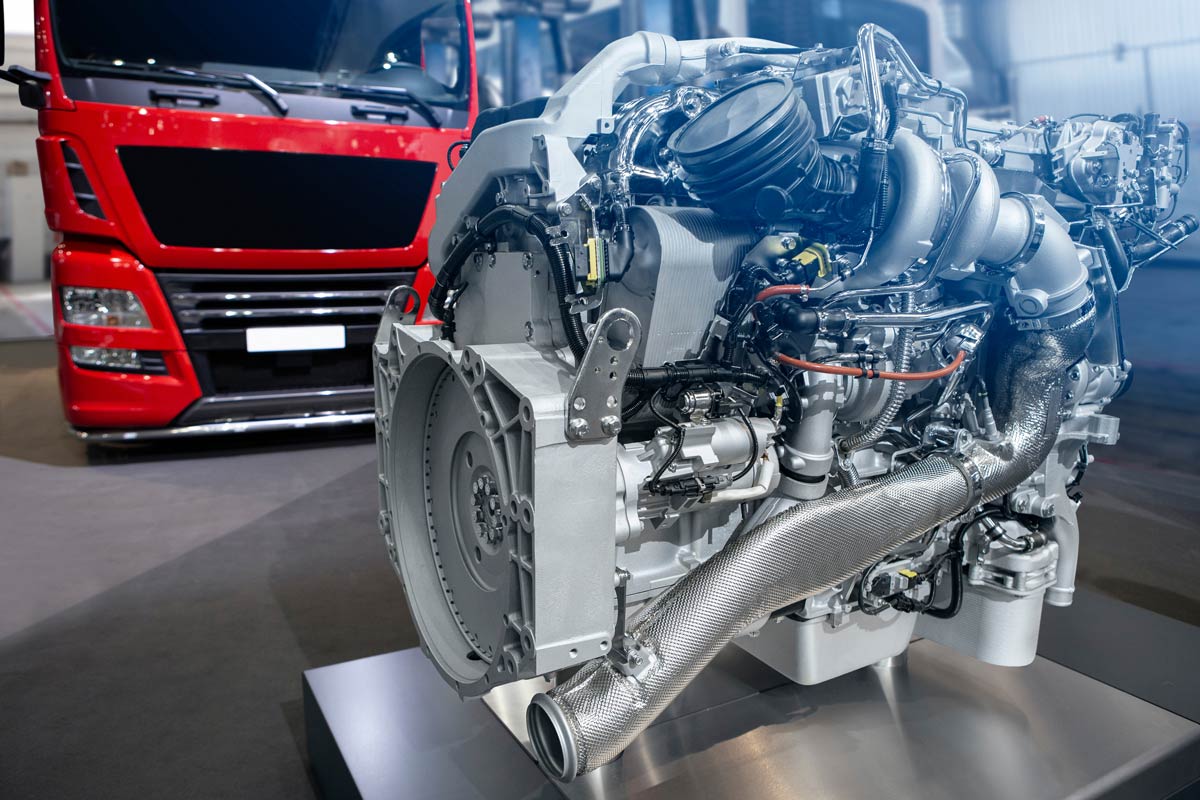

Automotive Leak Testing Solutions

Leading automotive manufacturers and integrators worldwide rely on InterTech Development Company’s patented technology and proprietary engineering skills for leak testing and calibrating leaks, functional testing including lifecycle testing, hydraulic testing, mechanical testing, and electrical testing.

InterTech invests considerable time and engineering talent in developing optimized custom equipment solutions for leak testing, calibrating leaks, and validating test technology as well as functional testing. These R&D efforts have achieved unparalleled accuracy, speed, R&R, reliability, and convenience in production line leak testing, flow testing, and functional testing.

Applying best-match leak test technology as required, InterTech supplies elite manufacturers of automotive products, cost-effective leading-edge testing equipment to meet ISO/TS 16949 standards.

Features

InterTech’s turnkey automotive leak testing solutions and expertise feature:

- In-depth knowledge of industry requirements and detailed studies and applications for end-user product specifications

- Careful selection of best-match test instruments including the use and design of customized test sensors where applicable

- Optimization studies to decrease test cycle time by as much as 70%

- Expert fixture designs that are uniquely tailored to each product being tested

- System-level integration of hardware and software and data handling and storage for ease of access and use over plant-wide networks

- Management of temperature-related effects and other factors potentially compromising test integrity to guarantee a gauge R&R of 10% for entire test solutions

Leading-Edge Technology and In-Depth Experience

For more than five decades, InterTech has partnered with leading automotive OEMs and automotive suppliers helping market leaders meet ever more stringent leak testing application requirements within the performance demands of the global automotive marketplace.

ISO 17025 accreditation of InterTech’s Calibration and Applications Laboratory’s quality management system compliments its ISO9001 accreditation ensuring customers and end-users are assured of quality and proven standards at all stages within their supply chains.

Contact the team at InterTech Development Company to learn more about our automotive test solutions.

Consult Our Experts

Please contact InterTech for further information or help with your test application. We are happy to answer any questions you may have. Give us a call at 847-679-3377 or fill out the form and we'll be in touch as soon as possible.

*denotes a required field.