Leak Detection Equipment Company

Founded in 1973, InterTech Development Company is a world leader in test technology, specializing in instrumentation, automated leak test and flow test systems with 7 patented mass flow and hydraulic technologies as well as proven expertise in helium mass spectrometry.

InterTech Development Company-engineered automated leak test systems are utilized globally by manufacturers worldwide in the medical, automotive, and industrial markets.

proven to be the most cost-effective test technology for a wide range of Applications

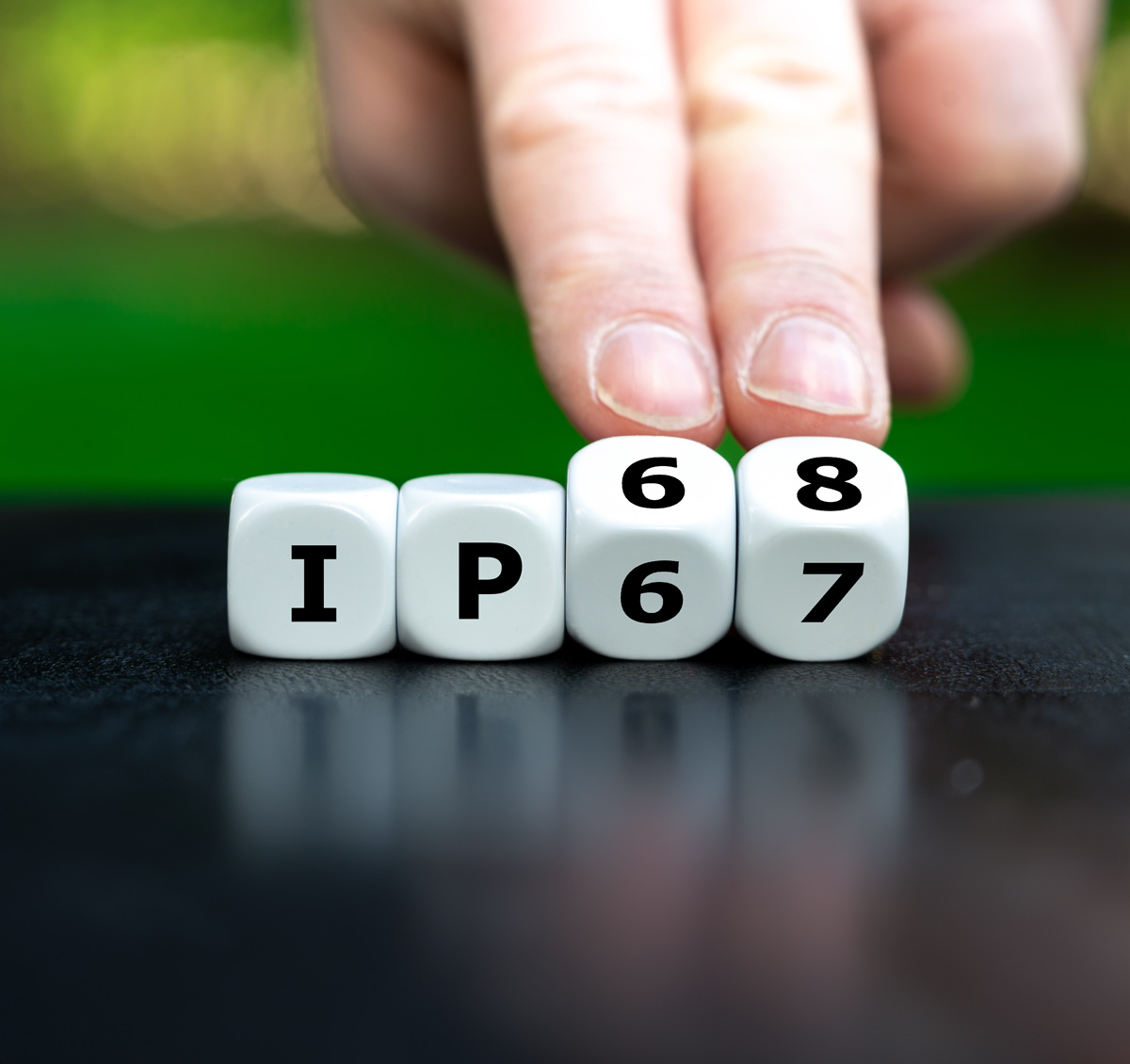

The InterTech M1075 High Speed Mass Flow Microscale Charge Volume Leak Test Instrument tests sealed Wearable Watches and Devices for IP67/68 integrity to ensure there is no water intrusion through the life of the product.

InterTech's proprietary charge volume leak test circuit ensures gross leaks are detected immediately and fine leakage is reliably detected and rejected.

Manually loaded and operated proprietary InterTech TechPressTM allows for safe and easy load and unload and chamber sealing eliminating carpal tunnel issues associated with other chamber sealing devices.

The InterTech M1075 High Speed Mass Flow Leak Test Instrument includes the Remote Start/Stop option and controls the test cycle. Watch and Wearable Devices are tested for 0.08 sccm at 49kPa (7.1 psig) at a rate of 60 parts per minute.

The Optimum Leak Testing Solutions

As a leak detection equipment company, InterTech’s competitive advantage is with leading-edge technology, in-depth experience, and single-source capability for all your testing and application requirements. Detailed engineering analyses of specific application requirements with best-match test technology, and maintaining best-of-class quality standards at the lowest cost, are available from InterTech’s Testing Applications Laboratory.

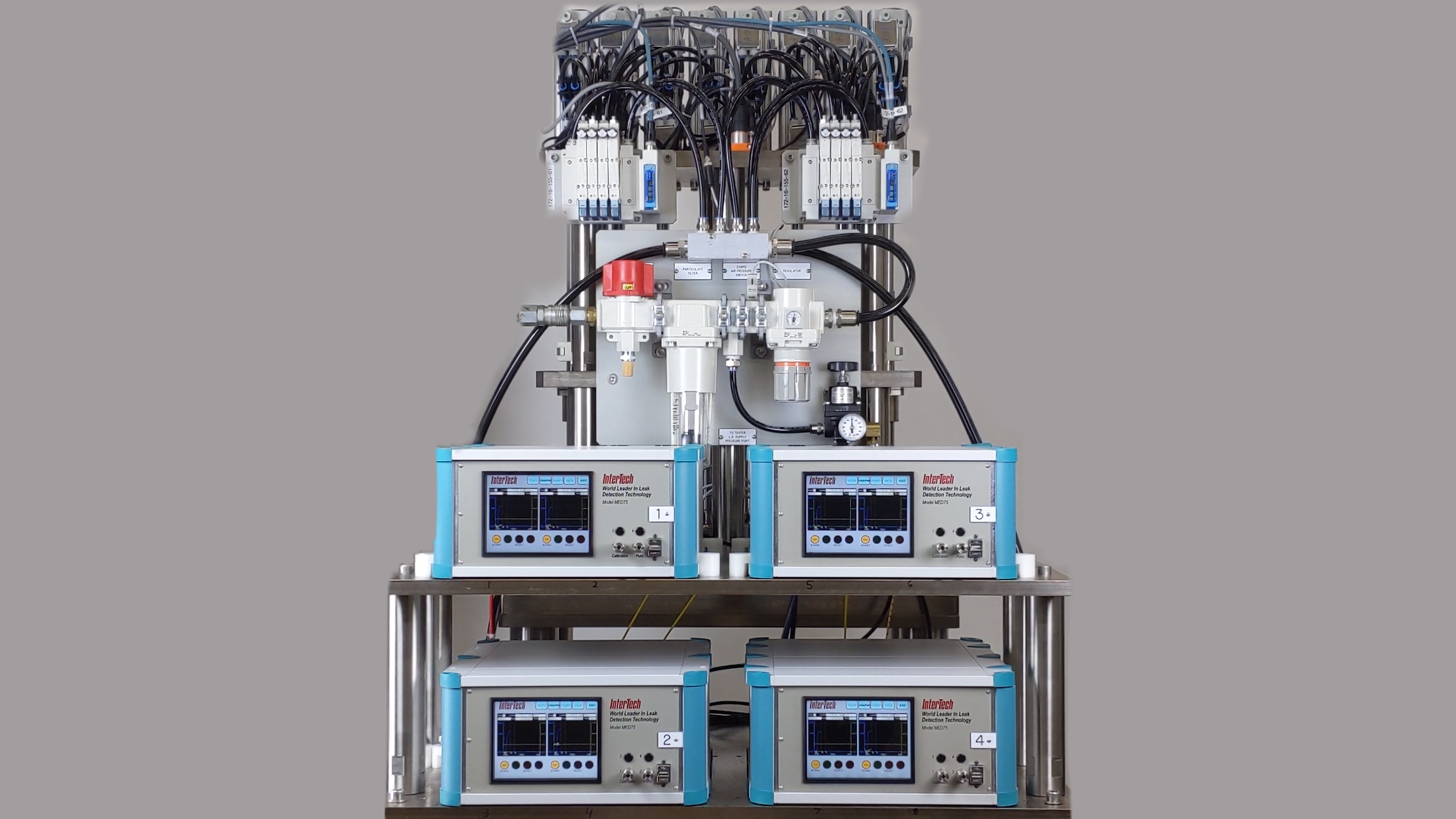

Catheter Test System

InterTech provide total test solutions for testing various types of catheters. For instance, multi-lumen catheters are sequentially leak and flow tested at a fast speed using InterTech MED75y two independent channel test instrument.

Container Closure Integrity (CCI)

Proven InterTech Microscale Technology measures leaks down to the equivalent of a 0.5 micron defect diameter.

ADAS Camera Leak Test Stand

The InterTech M1075 High Speed Mass Flow Charge Volume Leak Test Instrument tests sealed EV Cameras for IP67 integrity to ensure there is no water intrusion through the life of the product.

Wearable Watch Leak Test System

The InterTech M1075 High Speed Mass Flow Microscale Charge Volume Leak Test Instrument tests sealed Wearable Watches and Devices for IP67/68 integrity to ensure there is no water intrusion through the life of the product.

EV/AV Application

Power semi-conductor coolers are leak tested and gaged at a rate of 128 parts/hour.

ICE Application

Fixture ready station tests a family of machined magnesium cases & covers. Parts are robot loaded & unloaded, tested & marked, at a rate of 106 parts per hour.

The World Leader in Test Technology

Latest News

View some of InterTech's latest news posts.

Upcoming Tradeshow: 2024 Assembly South

Tradeshow Information:

Date: May 1st - 2nd

Address: 201 Rep. John Lewis Way S.

Nashville, TN

InterTech's Booth Details:

Booth #: 1065

Consult Our Experts

Please contact InterTech for further information or help with your test application. We are happy to answer any questions you may have. Give us a call at 847-679-3377 or fill out the form and we'll be in touch as soon as possible.

*denotes a required field.