InterTech Technology

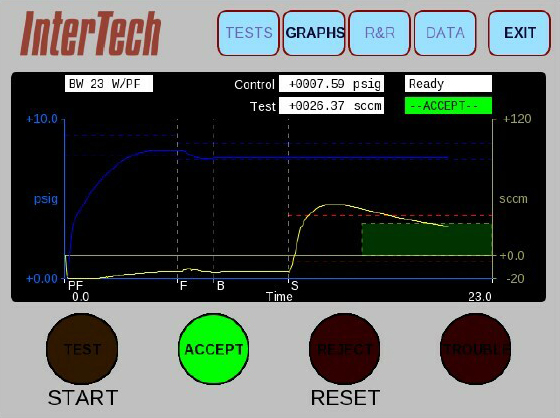

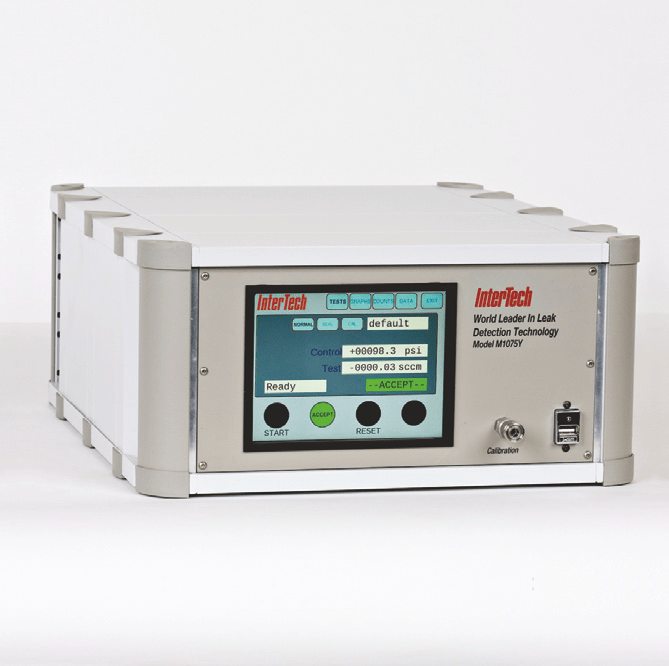

As a world leader in Test Technology, InterTech has leak & flow testing solutions for leak testing using dry air of pressure decay testing and mass flow testing. Many make mistakes of equating the upfront costs of a leak tester instrument with the costs of the leak testing in total. Over the economic life of a leak tester, the upfront costs of the test instrument are a mere fraction, often trivial, of the overall testing costs.

For a broad range of automotive, medical, and other industrial & consumer products, leak testing requirements before products are released to the marketplace have not changed. What has changed in recent years is several new technologies - some related to data handling and the Industrial Internet of Things and others relating to test techniques - that now change the calculus of determining best-match solutions for leak testing.

Test Methods

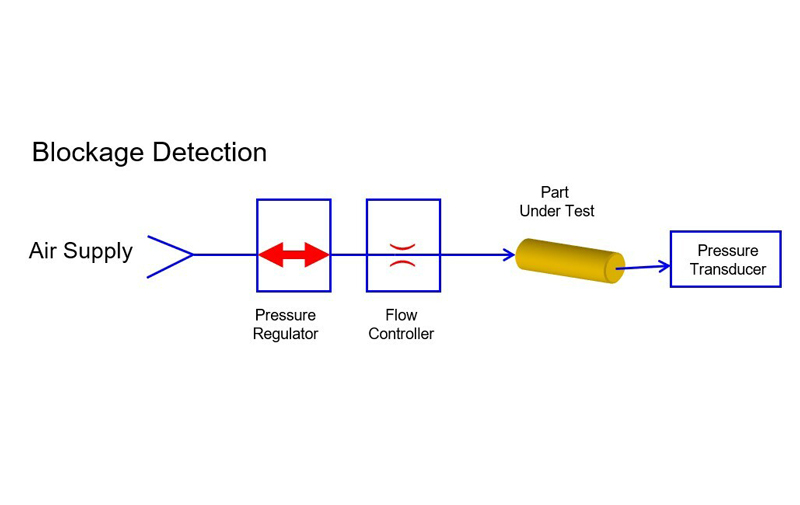

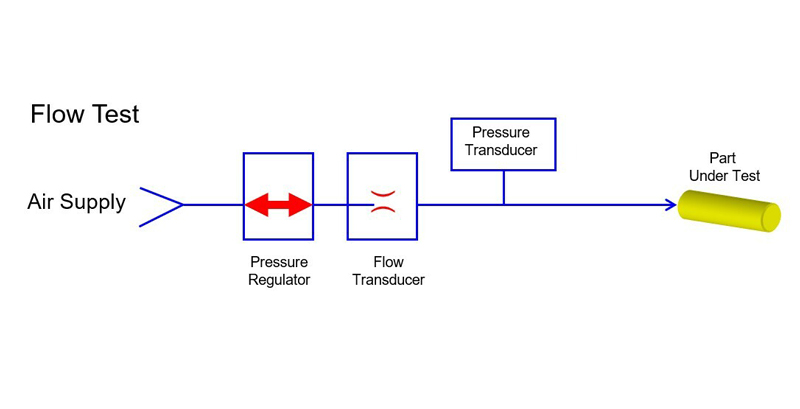

InterTech provides a wide range of measurement technologies including:

- Pressure Decay

- Differential Pressure Decay

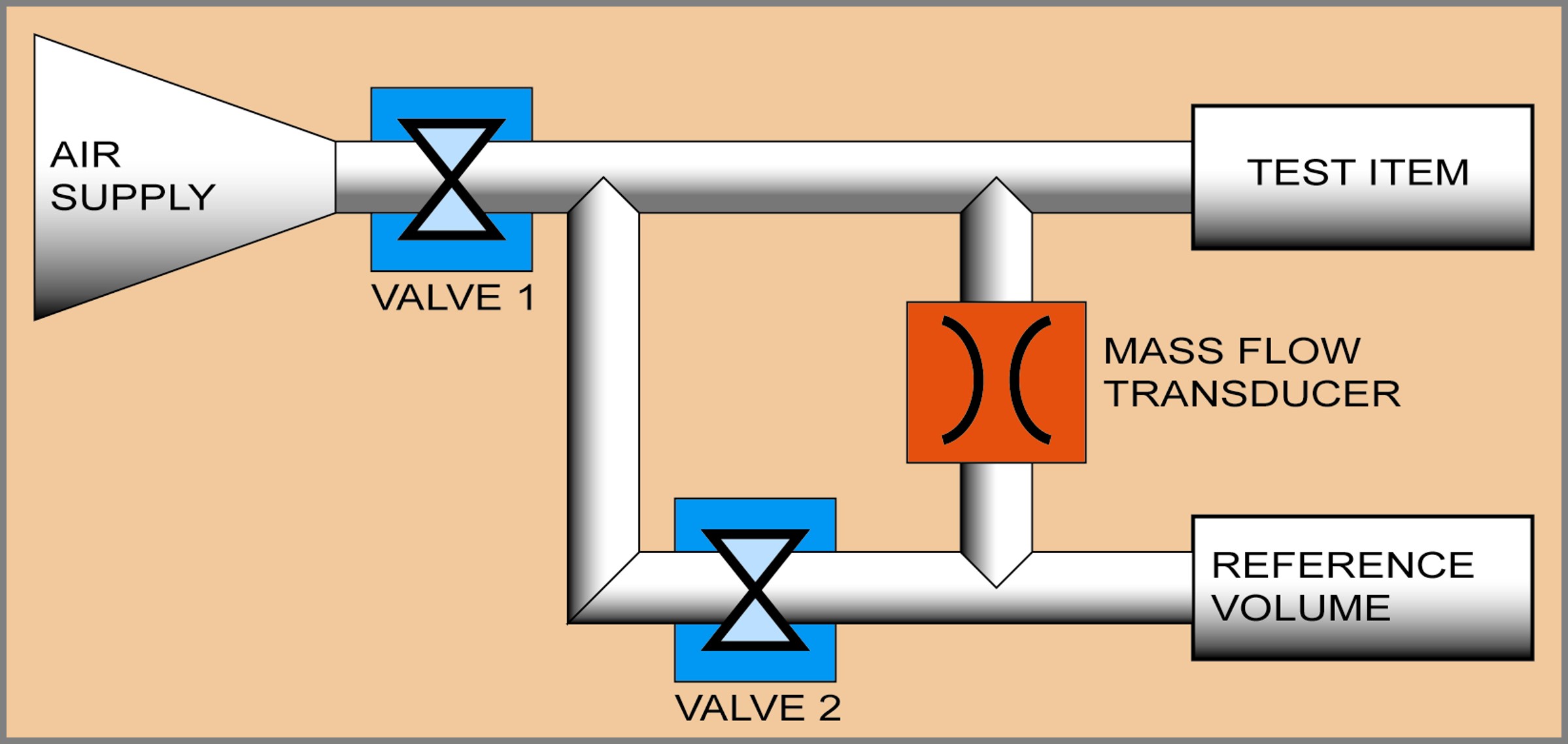

- Mass flow

- Helium

Customized Sensor Technology

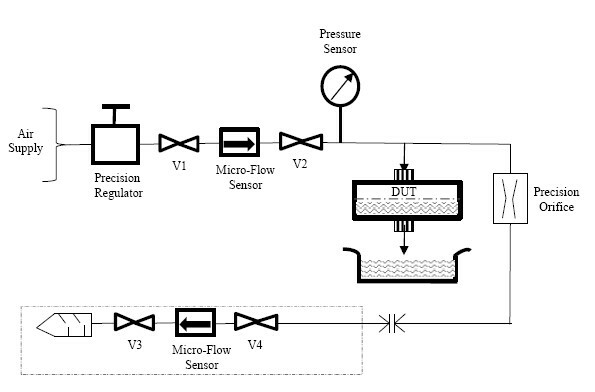

InterTech patented mass flow sensors that are tuned to the very precise testing conditions required achieve both shorter cycles and higher accuracy. These updated sensors - unlike generic sensors - maintain high measurement accuracy across a wider range of air pressures and temperatures, ambient temperatures, and random, short-duration disturbances in measured airflow. InterTech mass flow technology is uniquely capable of being implemented in applications requiring micro-scale leak rate measurements.

Patented Innovations for Large Volume Part Testing

InterTech has developed patented and proprietary test technology that dramatically improve the speed and accuracy of leak testing large volume products. Two new approaches that speed test cycles target the stabilization phase of a test cycle - the slowest part of a leak test, even with mass flow methods. One newly patented test technique eliminates turbulence to help speed the stabilization phases of test cycles.

Another new approach to reducing stabilization times and variations is by extracting the warm unstable air from the test part and replacing it with stable air, at the correct test pressure, that is ready to be measured for the leak rate value.

Detail information on InterTech's test technologies and applications are described in adjacent pages.

Consult Our Experts

Please contact InterTech for further information or help with your test application. We are happy to answer any questions you may have. Give us a call at 847-679-3377 or fill out the form and we'll be in touch as soon as possible.

*denotes a required field.